If you’re a professional carpenter, reducing air compressor noise is one of the things you may have thought about many times, but haven’t done so to date.

Although the air compressor sound may not be as loud as other woodworking machines, always turning and keep it on for long periods of time will annoy carpenters while working in the workshop.

You might say that the air compressor sound is not as annoying when compared to other woodworking machines, but after reducing the air compressor noise, you will find that doing so will benefit you and your colleagues.

In this article, we will discuss ways on how to quite an air compressor and we will show you the best ways of air compressor noise reduction.

Please stay with us.

Air Compressor Noise

Air compressors play a key role in supplying the required air pressure to the wood industry, paint industry, and other industries.

In long-term use of compressors, it can be annoying to hear so much noise.

Lichtenberg Wood Burning eBook

Download Lichtenberg Wood Burning eBook

One of the modern techniques for creating wooden artwork is called Lichtenberg wood Burning. In this eBook, we are going to introduce this newfound art to you.

This technique is known with some different names such as Lichtenberg wood burning, fractal wood burning, and electricity wood art.

This technique should not be confused with wood burning art or pyrography. The art of pyrography on wood is the art of creating motifs and designs by burning with hot metal tools on objects such as wooden surfaces.

Lichtenberg burning is a wood-burning technique for creating designs with electricity.

This eBook is a comprehensive guide on Lichtenberg Wood Burning. All you need to know for Lichtenberg Wood Burning is here.

This is a limited-time offer, order now to get access to the future eBook releases.

For this reason, we can reduce the noise of air compressors by using a number of techniques, which we will introduce later, but first, you need to know some tips in the woodworking workshop.

In fact, machines such as air compressors that the operator has no direct relationship to should be used in a separate workspace so that their sound does not get around.

Air compressors can also be placed outside if the weather conditions and maintenance of the device are appropriate.

Ways to Reduce Air Compressor Noise

Use Ear Protector

Some compressors can emit as much as 5 dB, so it is advisable for workers working near compressors to be more cautious.

Using an ear protector to protect the ear and hearing system is the smartest thing anyone can do when using noisy equipment.

Although you may think the ears are strong enough, the ears, like the eyes, lose their performance and power over time due to the high pressure, so you should not put your ear against the noise of the machines.

Earphones can be bought from online stores or the local woodworking tools store and be kept in your pocket.

Whenever you enter the workshop, put it on your ear before starting the air compressor or any other noisy device.

Remove Air Compressors From Your Workplace!

One of the easiest ways to get rid of noise is to keep the device at a manageable distance from your workplace.

For example, the end of the workshop and space away from your workplace is a good place to put air compressors.

The proper distance can reduce noise by up to 5%.

You can transfer air from the air compressor to other parts of the workshop using a piping hose.

Keep in mind that prolonging the hose size can cause a pressure drop.

If you need proper air pressure for things like paint, consider this.

Weather conditions also determine the possibility of using an air compressor inside or outside the work environment.

Insert the Compressor In the Anti-Noise Compartment

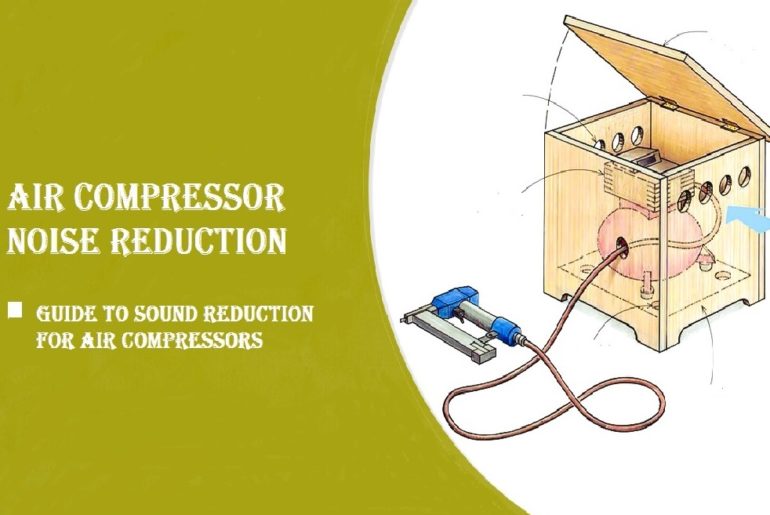

The most effective way to minimize the noise of an air compressor is to place it in the soundproof housing.

You can make a wooden box (any soundproof material) and put the air compressor inside it.

You can also cover the inside of the box using special foam to absorb the sound of the device.

For example, you can use the Ply Wood sheet to build an air compressor box and cover it with foam to absorb the air compressor sound.

Use Soundproof Curtains

Soundproof curtains can also be considered as a solution to reduce the noise of the air compressor.

It is another way of eliminating the noise of the compressor.

Place the device in a large wooden box or cabinet and then cover it with the soundproof curtains.

It is important to note that the outlet air should not be blocked.

Sound curtains can also be mounted directly above or around the edges of the air compressor. Even if you are not able to cover the device with the box, you can place the soundproof curtains around the device.

Change the Air Compressor Oil

Air compressor lubrication is one of the important things you need to take action for it.

Compressors, like all machines, contain metal parts that are constantly shaking.

For all parts to work ideally, lubrication must always be done around the joints.

Without lubrication, the metals are abraded and ultimately reducing the efficiency of the compressor.

If this continues, the compressor will produce more noise during operation, so a compressor must be lubricated regularly to keep it optimized.

Keep The Air Filter Clean

There are filters on the compressor that absorb airborne particles and prevent it from entering the cylinder.

This filter can absorb dust in the air when it is not dirty. In this case, the engine is pressurized and generates more noise.

Ideally, the air inlet filter should be cleaned after every 2 hours or less according to the conditions of the workshop.

Choose a High-Quality Air Compressor

In factories, industrial and home workshops, the noise of the compressor is a nuisance to everyone working there.

High noises are not only annoying but also slows down the work process due to the difficulty in communicating between workers when doing work.

Although compressor noise control methods are good options and maintenance should be done on a regular basis, compressor quality is the most important issue.

So when buying, try to choose the right air compressor.

Comments

Pingback: How to Make a Lichtenberg Resin Table | Wood Dad