Water is a natural component of a tree. Typically, water makes up more than half the weight of the woody texture of a tree trunk. When the tree dries, the wood immediately begins to give off some of its moisture to its surroundings. As the wood continues to dry, its dimensions and physical properties begin to change. But part of the water remains in the structure of its cell wall even after the wood is converted into lumber and other products. This article gives you everything you need to know about the moisture content of the wood.

Physical and mechanical properties, resistance to biodegradation, and stability of dimensions of any wooden product are affected by the water inside. Water affects almost all the properties of wood and its products, and therefore it is important to know the nature of wood moisture and its relationship with the microstructure and properties of wood.

Water in a Wood Cell

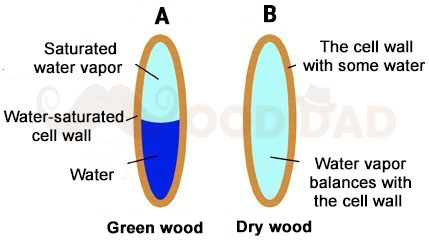

The figure below shows the location of water in a wood cell. As long as there is water in the cell cavity, the cell wall is saturated with water.

Part A shows the green wood cell. As the wood begins to dry, the water in the cell cavity first comes out. When the wood dries to the point where the water in the cell cavity is removed, we say that the wood is completely dry. In Part B, see a wood cell in the dry state. There is no more water in the cell and the moisture in the cell wall has decreased.

Different States of Water in Wood

Based on this, different states of water in the wood cell can be classified into three states:

Free Water

Free water is water that is found as a liquid or vapor inside the cavity of a wooden cell. Given that this water is held by the force of “Capillary action” and in the hot and dry state is easily removed from the wood, or in other words, in the process of drying wood, in the early stages when this water leaves the wood, it is called “free water”.

Bound Water

This type of water is located inside the wall of wood cells with the help of surface adsorption forces attached to the molecules of cellulose chains, and compared to free water, its separation from wood requires more energy. Hence, when the wood dries, it first loses free water and then part of the bound water.

Lichtenberg Wood Burning eBook

Download Lichtenberg Wood Burning eBook

One of the modern techniques for creating wooden artwork is called Lichtenberg wood Burning. In this eBook, we are going to introduce this newfound art to you.

This technique is known with some different names such as Lichtenberg wood burning, fractal wood burning, and electricity wood art.

This technique should not be confused with wood burning art or pyrography. The art of pyrography on wood is the art of creating motifs and designs by burning with hot metal tools on objects such as wooden surfaces.

Lichtenberg burning is a wood-burning technique for creating designs with electricity.

This eBook is a comprehensive guide on Lichtenberg Wood Burning. All you need to know for Lichtenberg Wood Burning is here.

This is a limited-time offer, order now to get access to the future eBook releases.

Structural Water

Structural water is present in the molecular structure of the cell membrane and is not easy to separate from the wood. This water has no effect on measuring the moisture content of the wood.

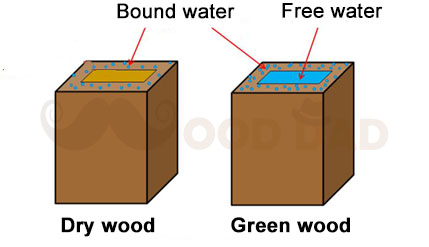

In the figure below, you can see the difference between free water and bound water. Free water that is in the cell cavity can be easily removed. Also, in dry wood, part of the bound water is lost.

What is Fiber Saturation Point?

The fiber saturation point is a term used to denote the point in the drying process at which only water bound in the cell walls remains – all water remaining, called free water, will be removed from the cell cavities. In other words, the point at which all the water in the cell cavity is removed but the cell wall is saturated with water is called the fiber saturation point (FSP).

FSP is a critical point because below that, the change in wood moisture causes a change in its properties. The moisture content of the wood at this point is about 30%. If dry wood is used in carpentry, the amount of moisture will always be less than FSP. For example, the moisture of wood used outside the building is usually between 10% to 12% and inside the building between 6% to 7%.

What Factors Determine the Moisture Content of Wood?

When there is free water and bound water in the wood (for example, in freshly cut wood) it is called “wet wood” or “green wood”. In this case, the amount of moisture in the wood is high and its amount depends on various factors such as tree species, different parts of the tree (stem, branch, heartwood, and sapwood, etc.), tree age, density, type of soil, and some other factors.

The Formula for Calculating the Moisture Content of Wood

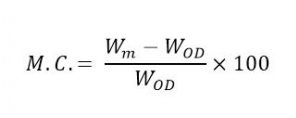

The moisture content of wood is measured as the relationship between the moisture content in kilograms (kg) and the amount of dry material in kg. With this explanation, the amount of moisture is defined as the ratio between the weight of water in the wet wood and the weight of the dried wood after drying.

You can see the formula for calculating moisture content in the picture below:

M.C. = Wood moisture content (percentage)

Wm = Weight of wet wood

WOD = Weight of dried wood

Wood Hygrometer

The method of measuring wood moisture using the electric hygrometer, which has spread among carpenters and experts in the wood industry, has become popular due to the high speed of obtaining wood moisture.

Advantages of electric hygrometer:

- Quickly measures wood moisture

- Measurement does not require special expertise

- The device is light and portable

- Low cost

Relation of wood moisture with the environment

Wood is a “hygroscopic” substance and is quite sensitive to moisture in liquid and vapor states; This means that when a piece of dry wood is placed in a humid environment, it absorbs moisture, and if a wet wood is placed in a dry environment, it loses its moisture. When the wood moisture eventually adapts fully to the ambient conditions, the wood is said to have reached its equilibrium moisture content (EMC).

Moisture Content of Wood for Woodworking

What are Acceptable Moisture Levels in wood for woodworking? Before we see what the acceptable moisture content of wood for woodworking should be, we must first get acquainted with the relative humidity.

Relative Humidity (RH)

Humidity is the concentration of water vapor present in the air. The relative humidity (RH) of an air-water mixture is defined as the ratio of the partial pressure of water vapor in the mixture to the equilibrium vapor pressure of water over a flat surface of pure water at a given temperature.

Let’s ignore these scientific definitions! We all feel the humidity of air in humid climates and also recognize the dry air.

What are Acceptable Moisture Levels in Wood for Woodworking?

Wood is hygroscopic, so the acceptable moisture content in wood for woodworking depends on two factors:

- The wood’s final usage.

- The average RH of the environment where the wood will be used.

So there is no general answer to this question. But based on common guidelines or recommendations, the acceptable moisture levels for wood for some woodworking projects are as follows:

- Wooden objects used indoors: 6-8%

- Wooden flooring: 6-9%

- Construction (Outdoor projects): 9-14%

Why is Wood Moisture Content so Important?

Since almost all physical, mechanical, and technological properties of wood are strongly dependent on its moisture content, its study is very important. Also, understanding the adsorption behavior and loss of wood moisture can be of great use in wood drying. In addition, this issue guides us in determining the amount of wood material in forest stands.

1- Correlation with Specific Gravity in Wood

Specific gravity indicates the amount of actual wood substance present in a unit volume of wood. Changing the moisture content directly changes the specific gravity of the wood. In this regard, the specific gravity of wood is always mentioned with its moisture content. The specific gravity of 12% moisture is called the normal specific gravity of wood. By knowing the percentage of moisture and specific gravity of wood in a forest mass, we can estimate the dry weight in that forest mass. The importance of this is well understood in paper mills that consider the dry weight of wood.

2- Correlation with Changing the Dimensions of Wood

These two properties are directly related to each other and always increasing the dimensions of wood is the result of increasing its moisture and vice versa. But at more than FSP, which varies from 25% to 50% for different species and habitats, the dimensions of the wood remain the same.

3- Correlation with Electrical and Thermal Properties of Wood

The electrical conductivity of wood increases with increasing moisture, but its electrical resistance decreases. Increasing the thermal conductivity of wood depends directly on the amount of moisture.

4- Correlation with mechanical quality

Changes in wood moisture directly change the resistance of wood to different forces. This is so important in wood mechanics that a certain coefficient is assigned to it. In addition, the results of all mechanical tests of wood, according to international standards must be provided at the moisture of 12%.

As the moisture increases, the strength of the wood decreases. Therefore, in wood consumption, its moisture is usually reduced to less than 20% by wood drying methods.

Comments

Pingback: Seasoned Wood, Everything You Need to Know - Wood Dad

Pingback: How to Burn Green Wood? - Wood Dad

Pingback: Thermowood - Introduction, Pros, Cons, And Uses - Wood Dad

Pingback: What is the Global Wood Price Scale? - Wood Dad