In this article, we’re going to give you some useful information to set up a woodworking workshop in a short time at home. Using these experiences and information, you can set up a professional woodworking workshop.

For completing this article, we’ve used the advice of some woodworkers with several years of experience.

In here, we have tried to provide you a complete tutorial, by combining the experience and academic knowledge of this field.

During these years, we have gained valuable insights on activities in various fields of wood and woodworking, and we have gained experience in the manufacture of different wooden structures, which we are going to present to you.

Among these valuable points, we can mention the principles of setting up a carpentry workshop, the principles of working with wood, the principles of cutting, fastening and assembling, the awareness of the types of wood and the tools needed to set up a carpentry workshop.

Getting to Know The Types of Wood And Their Features

Wood in human life has a long history, and from the past, to today it has been used so much to build the things we are already using. Over the centuries, wood has been used extensively in several types of wood arts and various structures.

To set up a carpentry workshop, basic information on the nature of wood seems essential. We need to know that when we work with wood, we are faced with a living creature, and we need to know a little about its nature and its physical and chemical properties.

Lichtenberg Wood Burning eBook

Download Lichtenberg Wood Burning eBook

One of the modern techniques for creating wooden artwork is called Lichtenberg wood Burning. In this eBook, we are going to introduce this newfound art to you.

This technique is known with some different names such as Lichtenberg wood burning, fractal wood burning, and electricity wood art.

This technique should not be confused with wood burning art or pyrography. The art of pyrography on wood is the art of creating motifs and designs by burning with hot metal tools on objects such as wooden surfaces.

Lichtenberg burning is a wood-burning technique for creating designs with electricity.

This eBook is a comprehensive guide on Lichtenberg Wood Burning. All you need to know for Lichtenberg Wood Burning is here.

This is a limited-time offer, order now to get access to the future eBook releases.

Using this information when working with wood in the cutting, grinding and assembling step, not only minimizes the risks to us, but also raises the quality of the produced product.

Density of Wood

Wood is a solid material and often with a density below 1 g / cm3 (1000 kg / m3). Of course, there are exceptions, and there are also a few wooden species that have a density of one gram and above 1 gram per cubic centimeter, which, if placed inside the water, will fall into it.

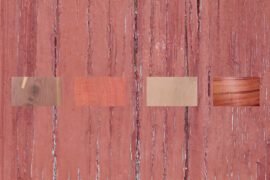

Texture of Wood

Wood is a porous and fibrous structure. This means that there are empty spaces between the components of the wood texture, which in some species can be seen with the naked eye.

The porosity of wood is one of the unique characteristics of wood species, which is one of the methods for identifying a variety of species.

Differences in the amount of porosity in different wood types create different experiences.

This point is very important in using or not using different types of wood for various uses.

By cutting the wood in tangential, radial or transverse directions, we will see different designs and different resistance.

Types of Wood

Most of the woody plants are divided into two groups:

- The trees with needle leaves, often with more soft texture – called softwood.

- The trees with broad leaves so-called hardwood, which usually has a harder texture than softwoods. Of course, there are exceptions.

For more info see types of wood for furniture.

Learn the Basics of Carpentry Before Setting up a Workshop

Most professional woodworkers recommend learning the basics of carpentry before setting up a carpentry workshop. This has two causes:

- If you really do not like carpentry, you’ll get tired and you totally became thoughtless of setting up a woodworking workshop. This will save you time and money.

- Avoid possible risks during working with woodworking tools.

There are several practical ways to learn the principles of carpentry for setting up a carpentry workshop.

So if you are a beginner, you will need to learn basic information and learn technical issues so that you won’t face any problems while working with carpentry tools.

The easiest and most reliable way is to use the experience of the good woodworkers of this field and learn the technical principles of working with wood and related tools.

By doing this, it’s easier and faster to be successful in achieving your purpose.

To find this valuable information for setting up a carpentry workshop and using each of them at different woodworking stages, there are a variety of ways that we will mention:

- Unpaid internships at private workshops

- Full-time work with salaries at private workshops

- Short-term classes held by the government

- Technical and vocational schools and public and private universities

- Short-term and long-term private classes

Some Tips For Set up a Woodworking Workshop at Home

In general, the tips you must follow to set up a workshop are as follows:

- Space needed to set up a woodworking workshop

- Tools to set up a workshop

- Safety at the home carpentry workshop

- Standard electric wiring at home woodworking workshop

Space Needed to Launch Woodworking Workshop

The space required to set up a woodworking workshop from 6 m² to the top is an acceptable space.

If a workshop is set up, it’s a problem for neighbors and you should choose types of woodworking art for these workshops that are not problematic and won’t produce noise or any other interruptions.

But if you have the right conditions to set up a workshop, be sure to isolate your workshop, so that you have made less disturbance to your surroundings.

Safety and Health at the Woodworking Workshop

You must be aware that during the commissioning phase of the woodworking workshop, you should observe the safety precautions of these types of workshops.

For example, in a workshop, you should use proper ventilation to avoid spreading dust. The presence of dust in the workshop space, in addition to the damage to the body, will also reduce your focus.

It is necessary to consider this tip in the home workshop. In a home workshop due to the small size of the space and the higher concentrations of dust, you should be more careful about this one!

Also, be sure to use the right light for the workshop. Apart from the usual safety equipment such as glasses, masks, suits, and handsets, be sure to have a mirror on the wall beside the first aid box to use it if necessary.

In the first aid kit, in addition to the necessary supplies, you should surely have artificial tears for washing your eyes. They can be used when facing a problem and external object entry.

See 10 Woodworking Safety Tips That Any Woodworker Needs To Know!

Tools Needed to Set Up a Woodworking Workshop

First, you do not need to provide the whole carpenter’s tool. The tools needed to set up a home woodworking workshop include:

- Variety of measuring tools

- Hand saw

- Screwdriver set

- Wood glue

- Circular saw and table

- Power Drill and drill bits

- Screws and nails set

- Variety of mounting tools like clamps set

- Safety tools like a fire extinguisher

- Hammer

- Nail gun

- Chisel Set

- Polishing Tool

- Sanding block set

Of course, depending on your type of work, some of these tools may be used, but in general, they are essential tools to set up a home carpentry workshop. See the best woodworking tools for beginners.

Standard Wiring For the Home Workshop

In a home workshop, change the wiring or inserting new switches and outlets should be done in accordance with safety principles.

In this step, be sure to use a high-strength power cable to use as a wire, which, when placed on the ground, will not damage and will not endanger you.

Be sure to use industrial switches and outlets. Use a protective fuse from the main power input to the workshop to avoid risking in the event of a problem at any stage of your work.

Standard wiring is very important in a workshop, try to consult with a specialist in this field.

Comments

Pingback: Air Compressor Noise Reduction | Wood Dad